- Who we are

- Products

- FILLERS

- New Hyper Clean fillers

- HEVF - Electronic volumetric filling system

- HEMF - Electronic mass meter filling system

- HEVS - Electronic volumetric filling system for sparkling products

- HELC - filling system by level for carbonated products

- ELC - Micro brewery filling

- HRLF - Recirculation filling system

- Help Desk

- Media center

- News

- Contacts

- Careers

HEVS - Electronic volumetric filling system for sparkling products

FILLERS

New Hyper Clean fillers

HEVF - Electronic volumetric filling system

HEMF - Electronic mass meter filling system

HEVS - Electronic volumetric filling system for sparkling products

HELC - filling system by level for carbonated products

ELC - Micro brewery filling

HRLF - Recirculation filling system

HEVS - Electronic volumetric filling system for sparkling products

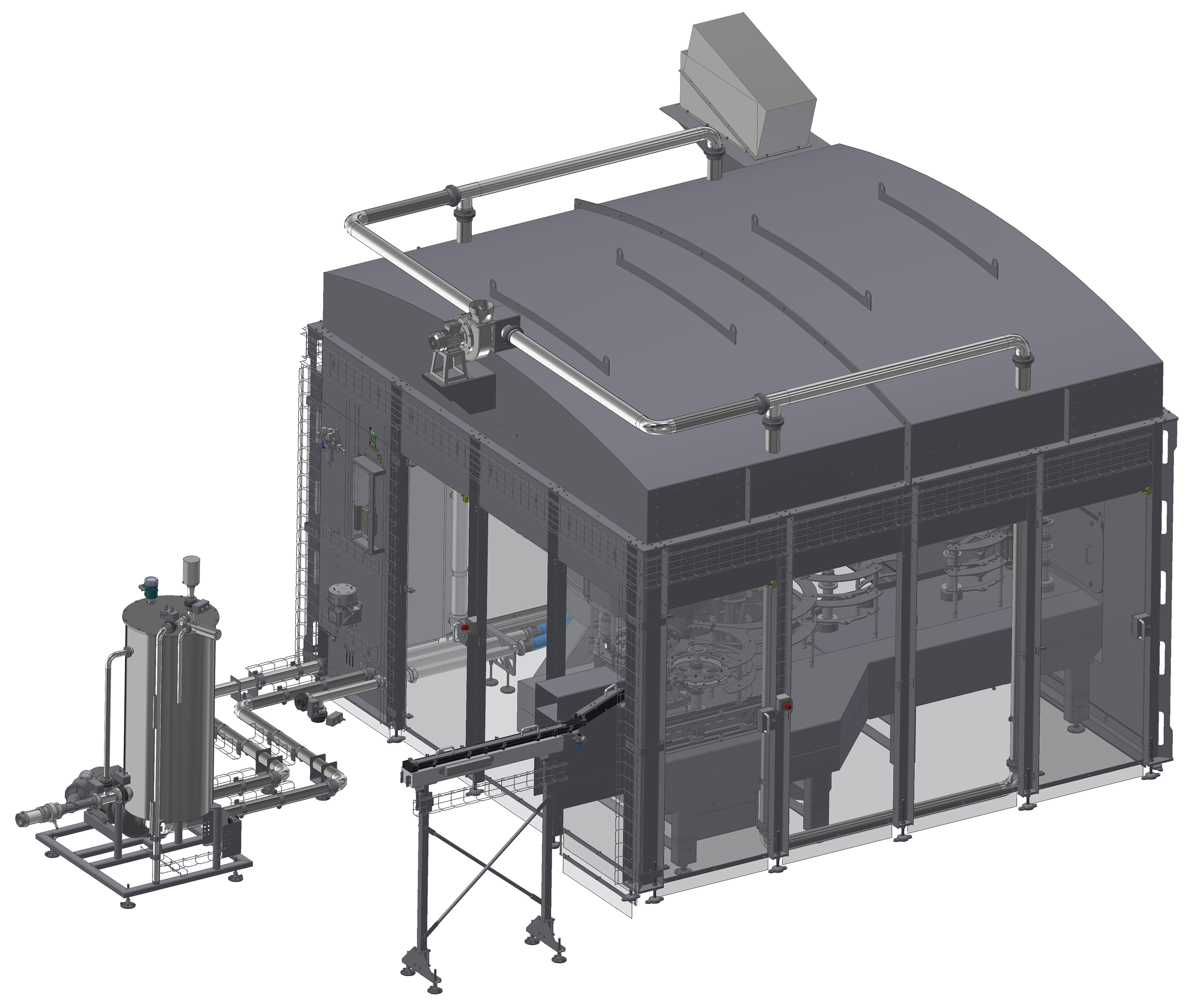

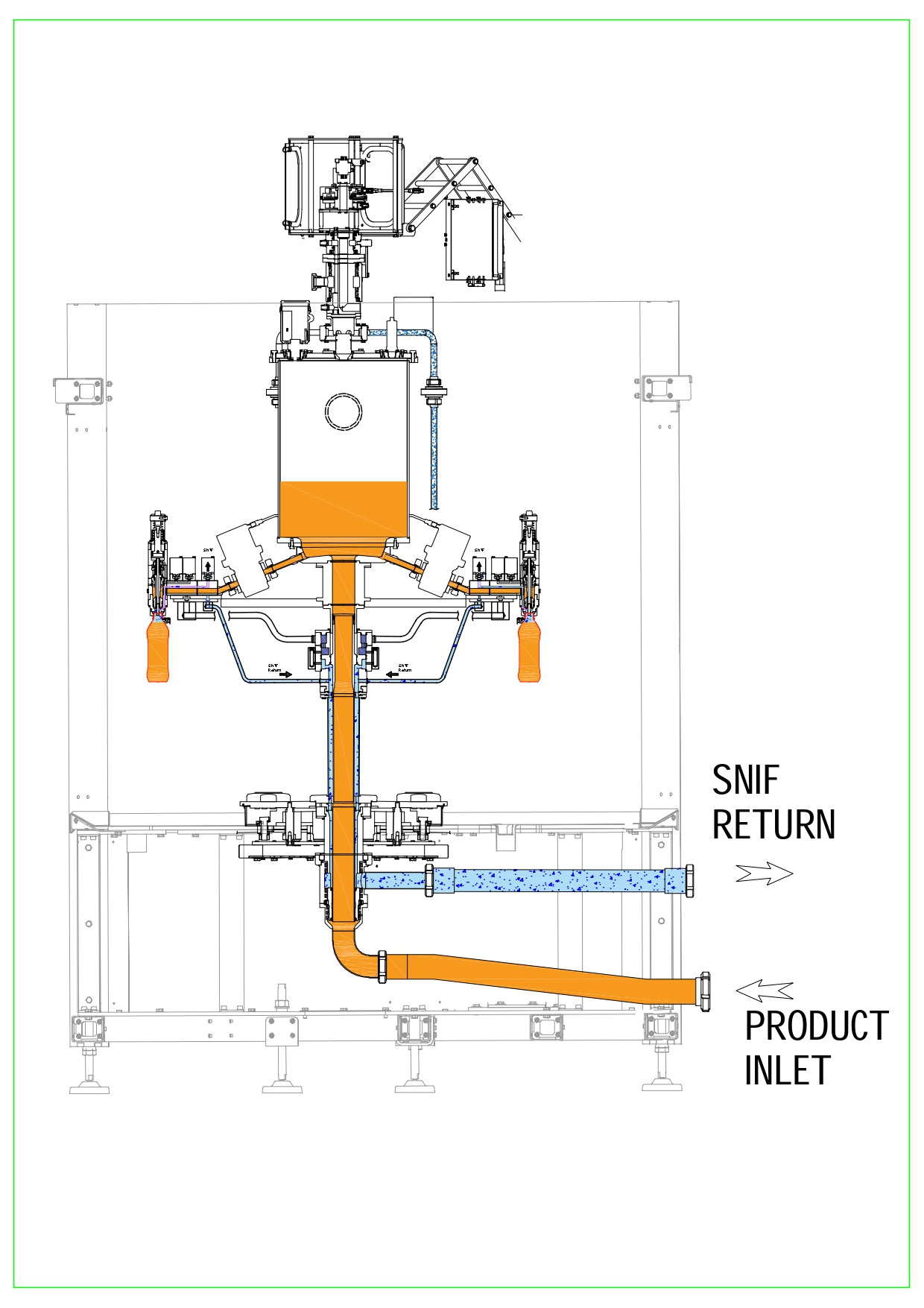

The filling machines of the HEVS series, manufactured according to the HYPER CLEAN characteristics, are suitable for the VOLUMETRIC filling of SPARKLING products in PET bottles.

HEVS fillers are characterized by:

- High precision flow meter installed for each filling valve;

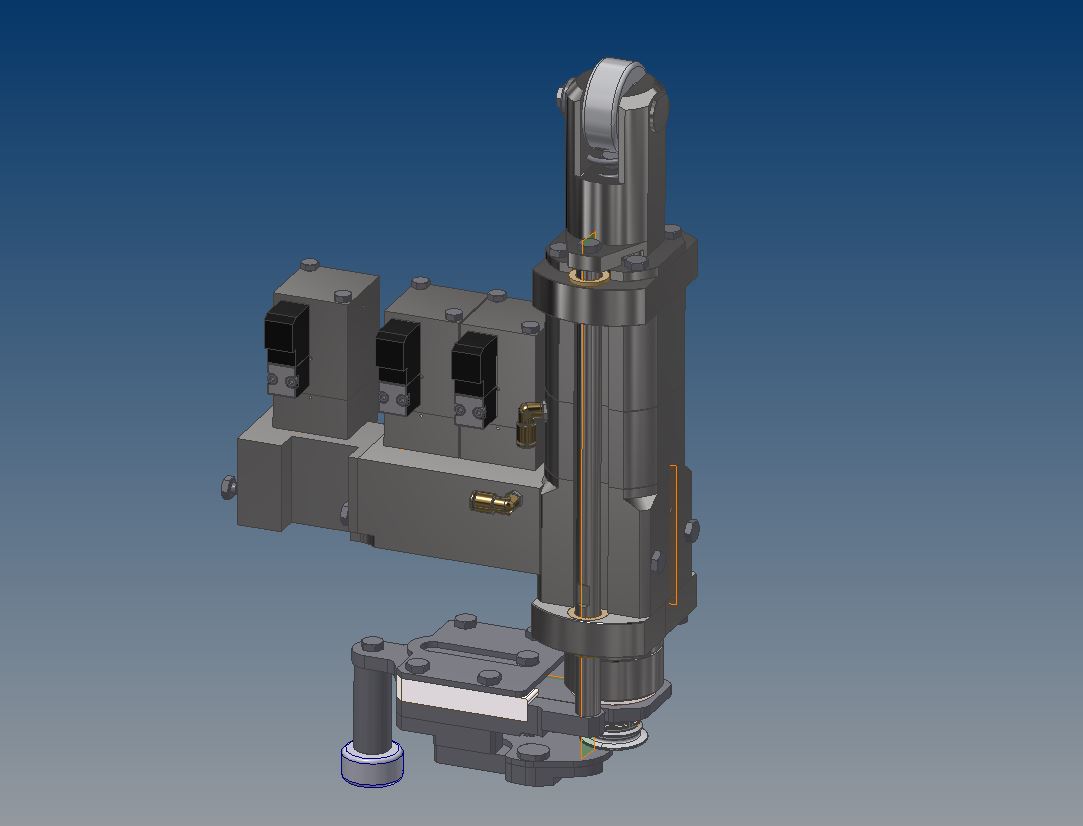

- Simplified filling valve, with reduced number of gaskets, capable of managing two filling stages (slow filling and fast filling);

- Lifting piston integrated in the valve body to ensure less movement of the bottle, a higher level of hygiene and a reduction in maintenance times;

- CO2 injection inside the bottle through a dedicated channel, completely sanificable;

- Cleanable sniff channel collected from each filling valve to one single drain outside the machine;

- Dummy bottle with automatic set up, directly placed on the filling valve;

- Higher filling temperature than filling with an electro-pneumatic filling valve.

The machine is complete, in the basic version, also with the following features:

- 18” HMI;

- Parameters of each format to be directly managed through HMI;

- Quick tool-less changeover of the bottle guide equipment;

- Compact frame for space saving in the filling line and reduced transport costs.

Available in various sizes to cover a wide range of production, the machines of the HEVS series are available in the filler/capper, rinser/filler/capper versions or in the ECOBLOC® version where the ENOBERG filler-capper block is combined with the SMI stretch-blow moulder.

PRODUCTION RANGE

PRODUCT | SPEED (BPH) | CAPACITY |

Sparkling water | 1.000 – 40.000 | 0.5 lt |

CSD | 1.000 – 38.000 | 0.5 lt |

OTHER DATA

Bottles capacity | 0.2 lt ÷ 3 lt |

Production speed | 1.000 ÷ 40.000 bph |

Filling valves | 30 ÷ 114 |

Available caps | Plastic screw cap |

Available bottle Ø | 44 ÷120 mm |

Available bottle height | 160 ÷ 340 mm |

Bottle handling | Neck Handling |

Operator panel | Touch screen 18" |

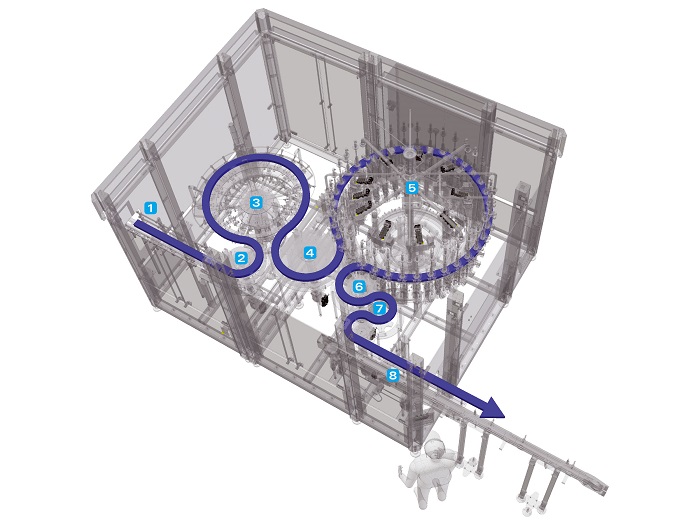

1INFEED CONVEYOR

PET bottles are transported inside the machine through an air conveyor. The bottle flow is regulated using a pneumatically operated gate which, depending on the condition of plant production, enables or blocks the bottles transfer to the first star wheel.

2BOTTLE TRANSFER: INLET - RINSER

Bottles coming from the air conveyor are transported towards the rinser. This transfer is performed through a rotating star wheel which receives the bottles from the air conveyor, handling them by the neck, and transports them towards the rinsing carousel.

3RINSER

The bottle coming from the star wheel reaches the rinsing turret where a rubber gripper grabs the bottle neck, and by using a mechanical cam system inverts the bottle (180 degrees) in order to have the bottle lip aligned with its rinsing nozzle. The nozzle is activated, dispensing water or air depending on the filling product and on the customers preference. At the end of the rinsing phase, the bottle is inverted again, coming back to the initial position.

The bottle is ready to be moved to the rinsing carousel. Each rinsing turret is equipped with a “no bottle-no spray" system: a sensor placed close to the rinser inlet detects the presence of the bottle. In the event that no bottle is detected, the correspondent turret will not perform any rinsing operation.

4BOTTLE TRANSFER: RINSER – FILLER

Bottles coming from the rinser are moved towards the filler. This transfer is performed through a rotating star wheel which collects the bottles from the rinsing turret, handling them by the neck, and transports them towards the filling carousel.

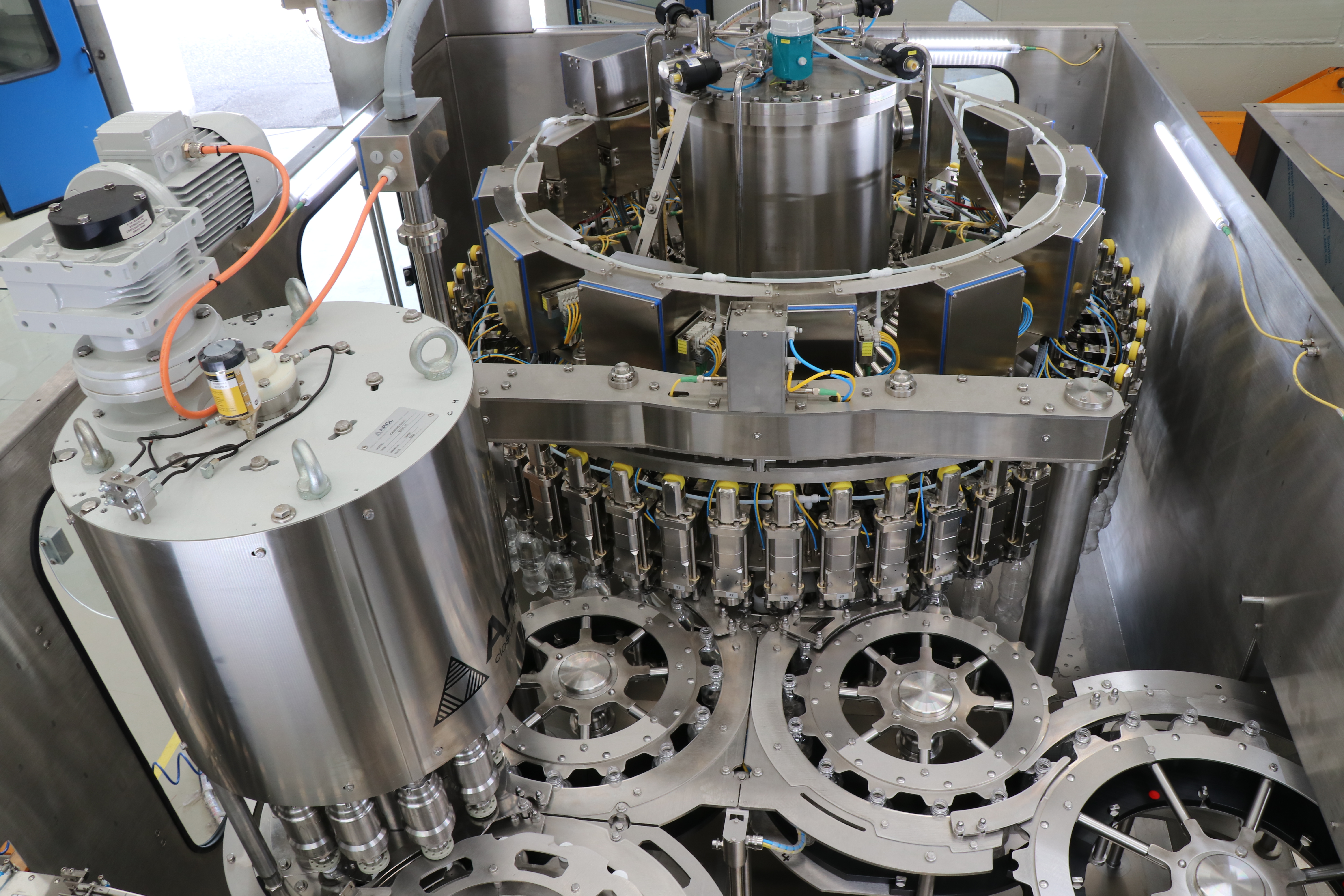

5FILLER

The bottle coming from the star wheel reaches the filling turret where the neck holder, directly connected with the filling valve, bring the bottle in contact with the filling valve in order to allow the filling.

The product tank, located inside the filling carousel, is specially designed to hold high pressure.

At the beginning of the filling, when the bottle is in contact with the valve, CO2 is injected inside the bottle in order to increase the pressure in the bottle and have a filing without loss of CO2 from the product and reducing foam creation while filling. The filling is electronic with volumetric flow meter. Each filling valve has a dedicated flow meter. When the filling starts, the flow meter detect the quantity of product going inside the bottle and stops the filling when reach the pre-set value from the format in use. While the product goes inside the bottle, the CO2 goes out from a dedicated channel. When the set filling volume is reached, the filling valve is closed and the sniff/decompression is done. A dedicated channel bring the pressure inside the bottle in a dedicated manifold and from there out of the filling area.

The filled bottle is ready to be transferred to the capper.

Each filling unit has a “no bottle-no fill” system: if the bottle is missing there is no filling.

6BOTTLE TRANSFER: FILLER – CAPPER

Bottles coming from the filler are moved towards the capper. This transfer is performed through a rotating star wheel which collects the bottles form the filling turret, handling them by the neck, and transports them towards the capping turret.

7CAPPER

The bottle coming from the star wheel reaches the capping turret where a star shaped mould allows the bottle centering under the corresponding capping turret. The cap coming from caps feeding system is picked up by means of a star wheel called "pick and place". The capping head collects the cap from the star wheel and it applies the cap to the bottle. Depending on the cap to be applied (plastic screw cap or plastic pressure cap), the capping system may be rotating or by-pressure.

The rinsed, filled and capped bottle is ready to be moved to the outlet conveyor. Each capping turret is equipped with "no bottle-no cap" system: in the event that no bottle is detected under the capping turret, the cap will not be applied.

8OUTLET CONVEYOR

The rinsed, filled and capped bottles are transported out of the machine through an air conveyor. This conveyor is equipped with automatic height adjustment which allows the bottle point of support to be tailored to the bottle height.

TECHNICAL DATA

Advantages

- Modular structure which can be customized;

- Compact filling module which minimizes the number of stars for bottle handling, while ensuring an easy access for maintenance and cleaning;

- Modular framework which allows optimization of the shipping dimensions, cutting the transport costs and making the machine suitable for standard road transport;

- Low operating and maintenance costs;

- Low risk of contamination, high level of hygiene;

- Excellent price performance ratio.

Standard accessories

Each HEVS machine is provided with:

- Guarding in tempered glass;

- Parts in contact with the product made in AISI 316

- 18” HMI (Human Machine Interface) touch screen, supplied by SMITEC;

- Pre-programmed recipes, enabling quick changeover at a software level;

- Quick bottle changeover parts;

- Flow-meter installed in proximity to each filling valve;

- Cap sorting system placed near the filling machine outside the filling area, at ground level, easy to inspect.

- Easily serviceable filling valve, completely made in AISI 316;

- Electronic Filling system;

- Automatic cleaning phases (CIP).

Optional

Available on request, it is possible to install on ENOBERG’s HEVS machine:

- Upper covering;

- Laminar flow to create an overpressure in the working environment and to prevent penetration of micro foreign objects in the machine;

- Components in contact with the product in AISI 316;

* The stated values are not binding, as they have to be confirmed by ENOBERG according to the user's production conditions.

Contact us

- ENOBERG S.r.l.

- Address: Via del Lavoro, 14

24060 Telgate BG

Italy - Phone: + 39 035 845908

- E-mail: info@enoberg.it

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Enoberg adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

ENOBERG S.r.l.

Sede amministrativa: Via del Lavoro, 14 - 24060 Telgate (BG) - ITALIA

VAT.: 04471940165 - C.F.: 01490080163 - R.E.A.

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

ENOBERG S.R.L.

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.enoberg.it

C.F. 01490080163 - P. IVA IT04471940165 - R.E.A. 210344

Iscr.Reg.Imprese 01490080163 - Cap. Soc. € 600.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

Unità produttiva: Via del Lavoro, 14 - 24060 Telgate (BG) – ITALIA Tel. + 39 035 845908 - Fax: +39 0345 40 209