- Who we are

- Products

- FILLERS

- New Hyper Clean fillers

- HEVF - Electronic volumetric filling system

- HEMF - Electronic mass meter filling system

- HEVS - Electronic volumetric filling system for sparkling products

- HELC - filling system by level for carbonated products

- ELC - Micro brewery filling

- HRLF - Recirculation filling system

- Help Desk

- Media center

- News

- Contacts

- Careers

New Hyper Clean fillers

FILLERS

New Hyper Clean fillers

HEVF - Electronic volumetric filling system

HEMF - Electronic mass meter filling system

HEVS - Electronic volumetric filling system for sparkling products

HELC - filling system by level for carbonated products

ELC - Micro brewery filling

HRLF - Recirculation filling system

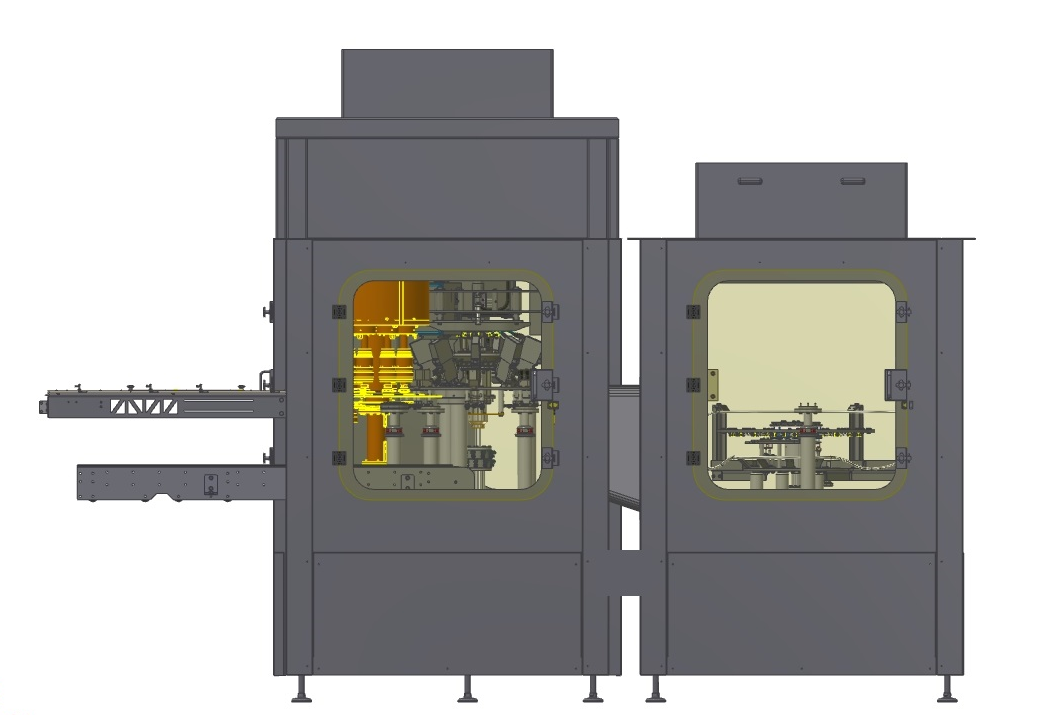

New Hyper Clean fillers - New Hyper Clean fillers

Cleanliness, stability and simplicity as strengths for our fillers.

Thanks to Enoberg's 40 years of experience in the construction of filling machines, we have designed an innovative and cutting-edge series of machines, set to become a reference point in the bottling sector.

The HYPER CLEAN series offers as strengths:

- high level of hygiene;

- ease of use and maintenance;

- reliability and structural solidity.

- compact footprint

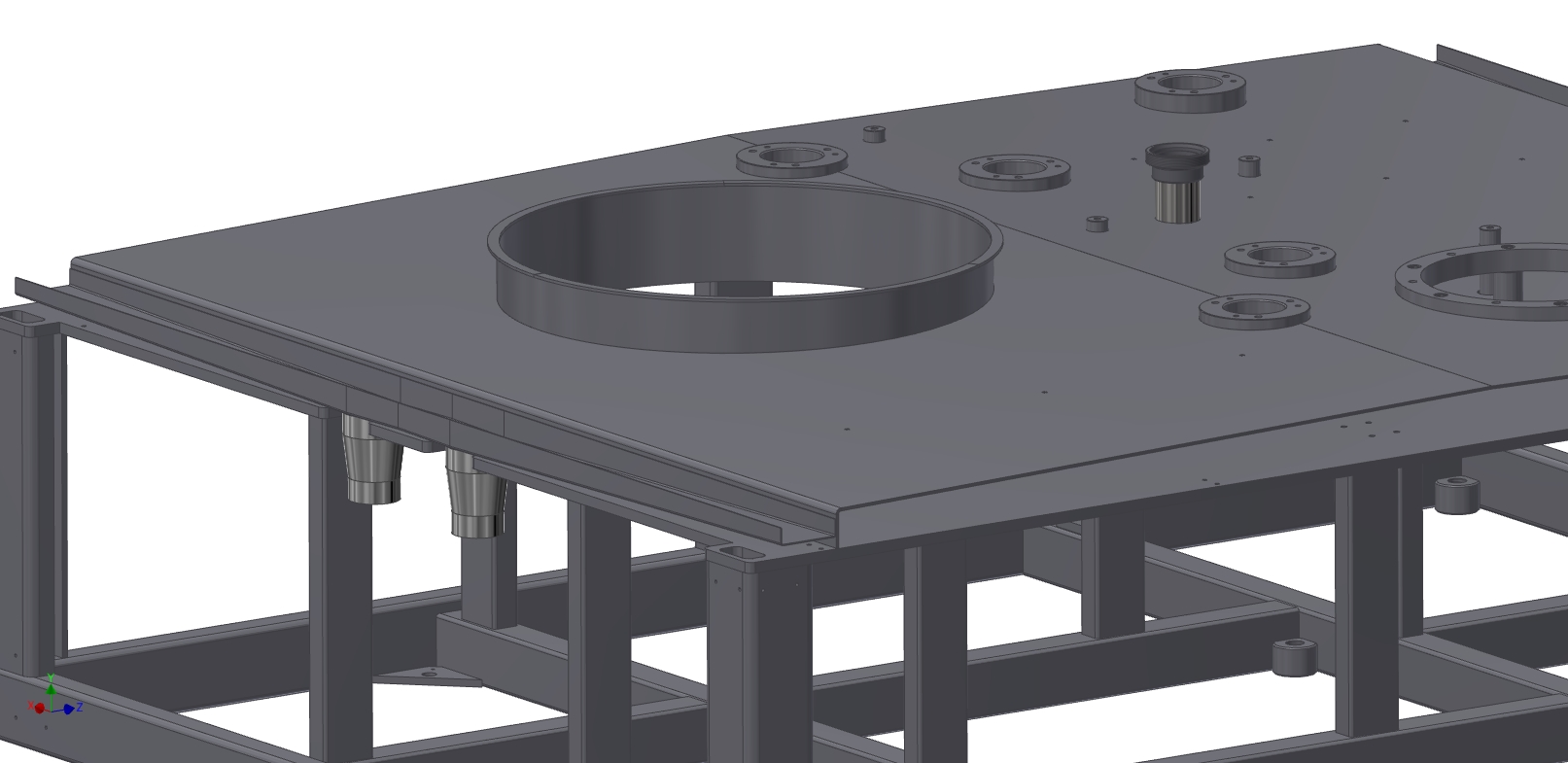

The machine structure is made with the following characteristics:

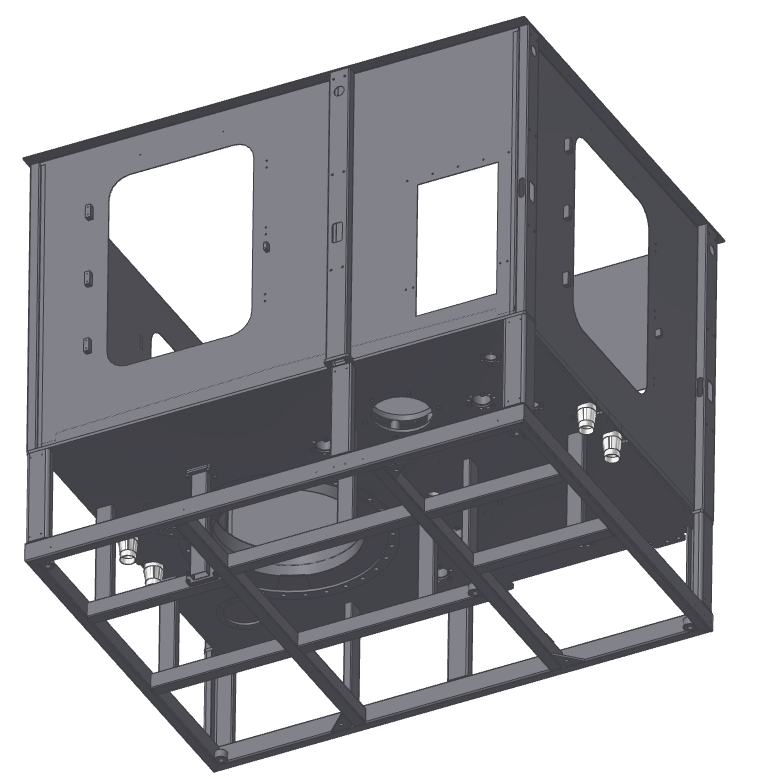

- small size suitable also for the small production plant;

- frame made of AISI 304 stainless steel, without iron parts

- fully welded frame;

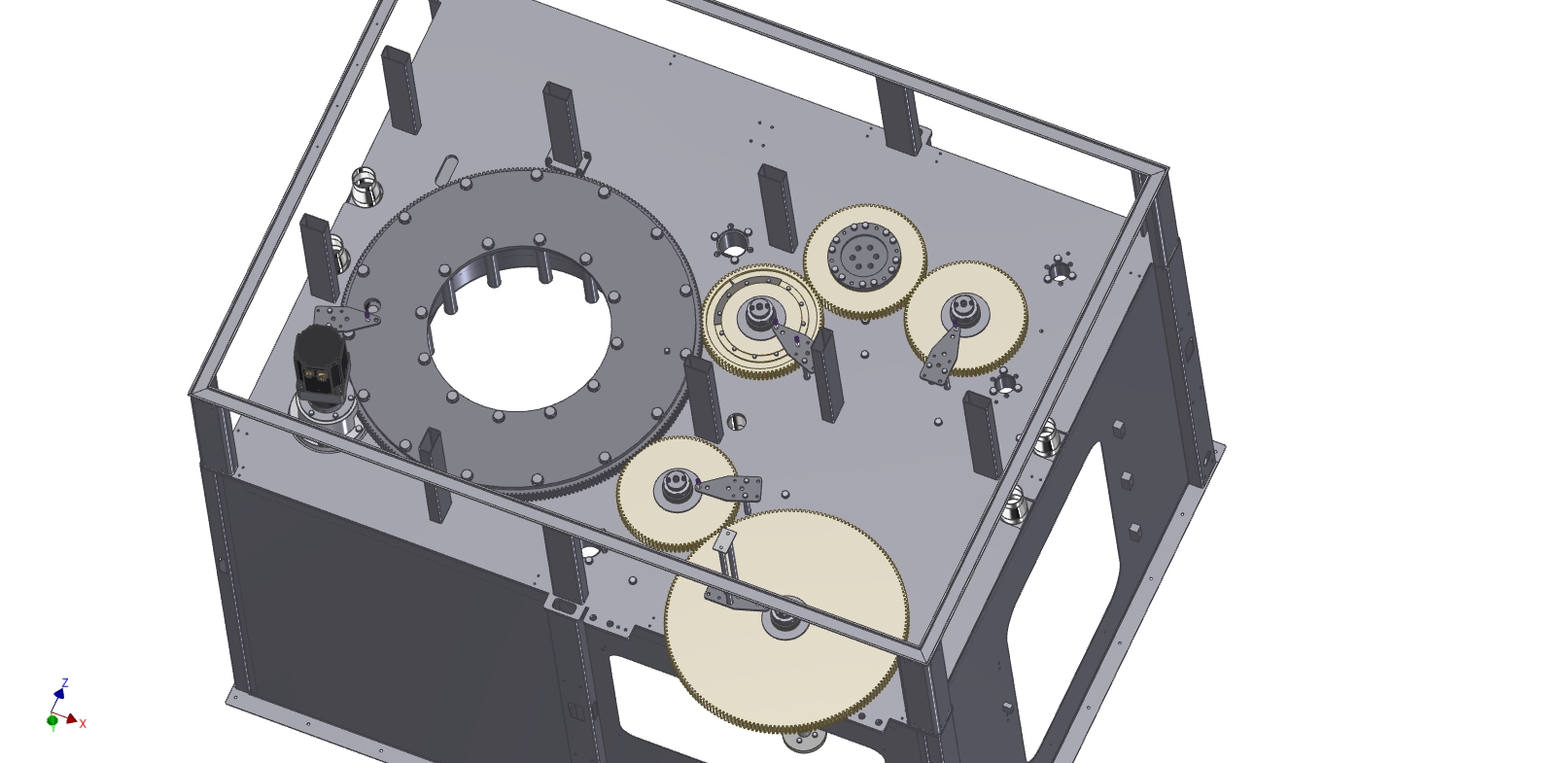

- total and complete separation between the filling area and the transmission area;

- rotation of the carousels guaranteed thanks to a slewing bearing and gears, to guarantee perfect synchronism in every occasion.

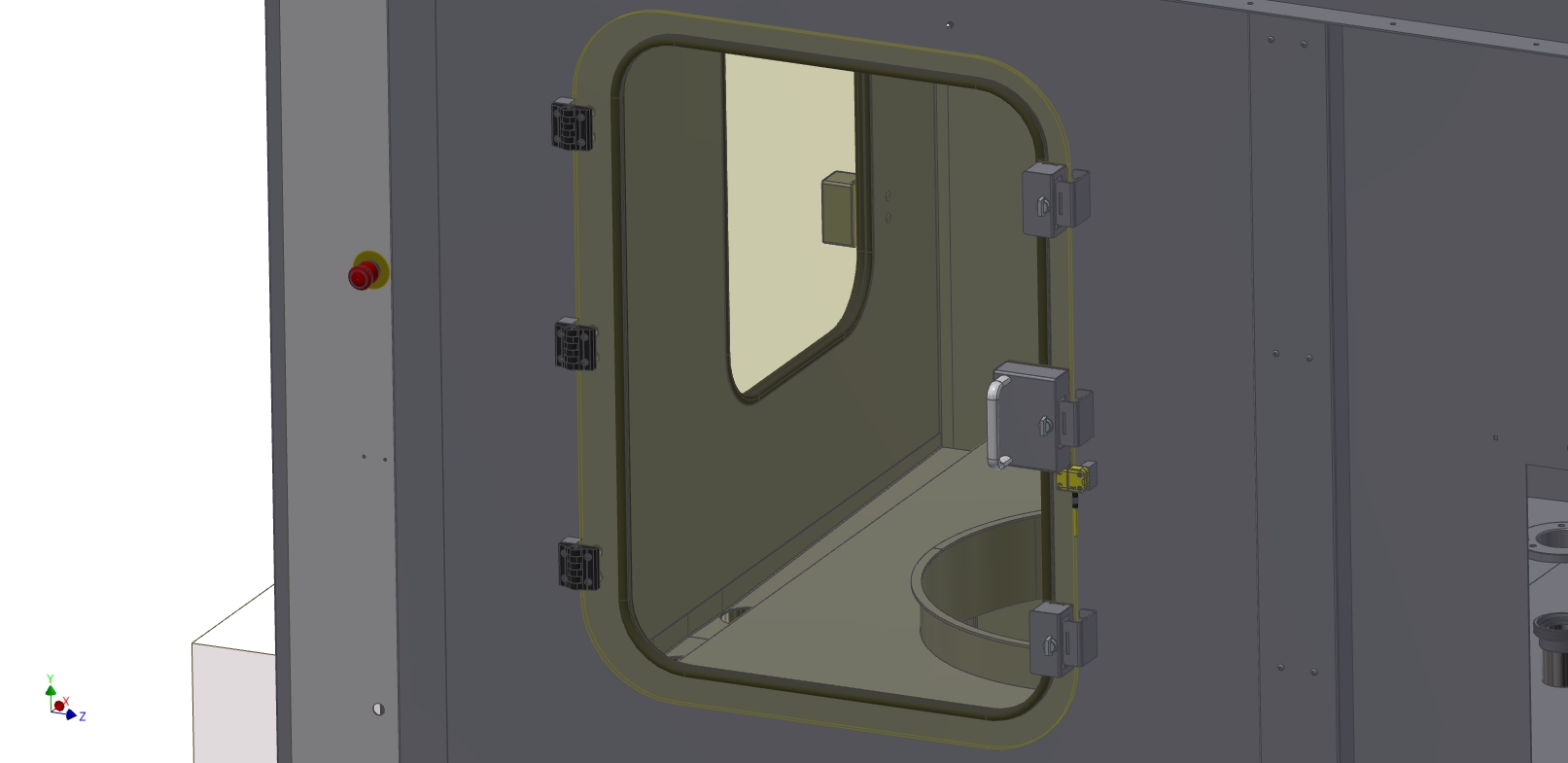

The high level of hygiene is obtained thanks to:

- inclined base plate to allow the constant drainage of liquids outside the filling environment;

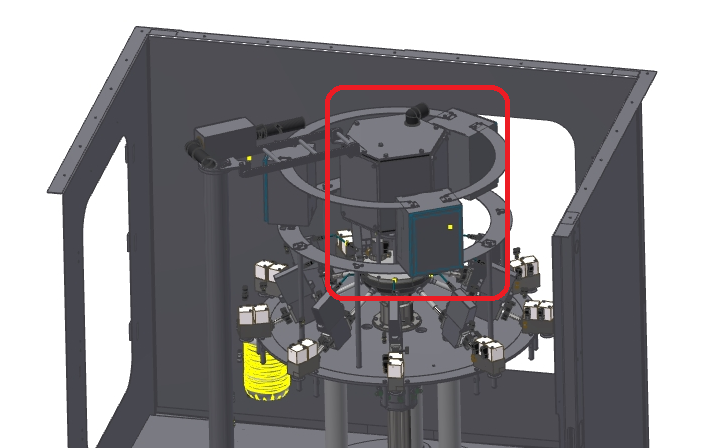

- separation between wet collectors (filling product and washing solution), located in the lower part of the structure, and electrical and pneumatic inlets, located in the upper part;

- electrical and pneumatic components closed in hermetic sealed boxes;

- reduction of possible contamination (e.g. reduction of gaskets inside the filling valve);

- dedicated terminal part of filling valve for each product to be filled.

The new machines also have the advantage of:

- reducing the dimensions in the bottling line, thanks to the more and more compact layouts;

- facilitating unloading and positioning in line, thanks to the solid structure;

- reducing maintenance times and costs, thanks to the new construction features.

.

Contact us

- ENOBERG S.r.l.

- Address: Via del Lavoro, 14

24060 Telgate BG

Italy - Phone: + 39 035 845908

- E-mail: info@enoberg.it

- Monday - Friday: 08:00 - 12:00 / 13:30 - 17:30

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Enoberg adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

ENOBERG S.r.l.

Sede amministrativa: Via del Lavoro, 14 - 24060 Telgate (BG) - ITALIA

VAT.: 04471940165 - C.F.: 01490080163 - R.E.A.

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

ENOBERG S.R.L.

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.enoberg.it

C.F. 01490080163 - P. IVA IT04471940165 - R.E.A. 210344

Iscr.Reg.Imprese 01490080163 - Cap. Soc. € 600.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

Unità produttiva: Via del Lavoro, 14 - 24060 Telgate (BG) – ITALIA Tel. + 39 035 845908 - Fax: +39 0345 40 209